Titanium Grade 2/Grade 5 Forgings

Titanium Grade 2 / Grade 5 Forgings Manufacturer in Vadodara, India

Titanium Alloy Grade 2 Forging, Titanium Alloy Grade 5 Forgings, UNS R50400 Forgings Dealer, Titanium Gr 5 Forgings, Titanium Grade 2 Forgings, Titanium Gr.2 Forgings, Ti Alloy 3.7035 Forgings, Titanium Gr.5 Forgings, Titanium N56400 Forgings Manufacture in Vadodara, India.

GreatBolt Industries is one of the leading industries in manufacturing, supplying, exporting and one of the most popular stockiest for the forging made products. Our Titanium Grade 2/Grade 5 Forgings is one of the highly demanded products in the national as well as global market.

Forgings are basically a procedure that is done on various types of metals in order to convert them in various sizes, shapes, etc. Thus forging products are available in different thicknesses, dimensions, specifications, grades, alloys, shape, size, standards, etc. This process is done by hammering the metal or rolling, pressing, etc. The comprehensive forces applied during the process are applied with the help of a die or a hammer.

Moreover, there is various process of forging like cold, forgings hot forgings, warm forgings, etc. Forging is unbeatable for its amazing features like good reliability, resistance, hardness, machinability, economy, and strength, etc.

Titanium Grade 2/Grade 5 Forgings is a durable product that can help you, in the long run, working in any application or industrial usage. The highly demanded grades in Titanium Forgings are Grade2/Grade 5 because such grades are easily usable even in the extreme high and low temperatures and workings.

The grade 2 titanium alloy is referred to as unalloyed titanium. Moreover, it is considered as one of the commercially pure titanium alloy types. It is majorly used in the application where the process of welding is frequent due to its excellent welding properties. Furthermore, it offers some of the great features such as good resistance; it is a light weighted grade of the alloy, etc.

Ti Alloy Grade 2 Chain, Titanium Gr 5 Chain Link, ASTM B348 Titanium Alloy Forgings, Titanium Grade 2 Bow Shackle, DIN 3.7165 D Shackles, Titanium Gr 2 Chain Link, Ti Alloy Grade 2 Forgings Exporter in India.

Titanium Gr.2 D Shackles, Titanium Grade 5 Forgings Stockholder, Ti Alloy Gr.5 Bow Shackle, Titanium Alloy Grade 5 Twist Link Chains, Titanium Grade 2 Forgings Supplier.

The grade 5 of titanium alloy is commonly used worldwide mainly in the oilfield workings. Moreover, it is an alpha-beta alloy type that has a combination of aluminum and vanadium. Titanium Grade 2 / Grade 5 Forgings is used in many of the application industries for such as automotive and trucks, aerospace, off-highway, and agricultural industries, ordnance, valves and fittings, industrial, hardware tools, power generation, hydrocarbon processing’s, chlorate manufacturing, medical industries, marine industries, and many more.

Titanium Forgings in the Titanium Grade2 as well the Grade 5 possesses excellent ductility and formability. PMI testing, mechanical test, ultrasonic test, spectro test, flaring test are some of the tests conducted on Titanium Grade 2 / Grade 5 Forgings before delivering it to the customers.

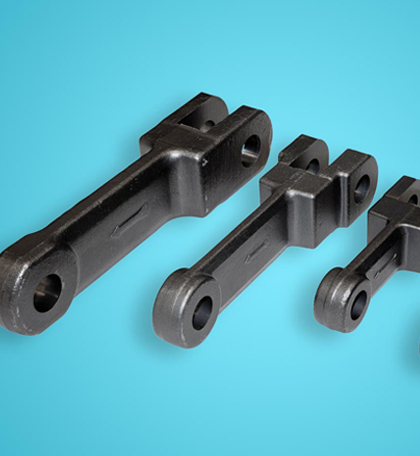

Titanium Grade 2 / Grade 5 Forgings Types

Titanium Grade 2/Grade 5 Chain

Titanium Grade 2/Grade 5 Chain Link

Titanium Grade 2/Grade 5 D Shackle

Titanium Grade 2/Grade 5 Bow Shackle

Titanium Grade 2/Grade 5 Rolled Ring

Specification of Titanium Grade 2 / Grade 5 Forgings

| Standard : | ASTM /ASME B348 / SB348 |

| Dimension : | ASTM, DIN, BS, GB, IS and all International Standards |

| Forged Between : | 2300/1700ºF (1260/930ºC) and air cooled |

| Severe Reductions : | Ingot breakdown, Roll forging, Drawing, Blocking and Backward extrusion - 2300ºF (1260ºC). |

| Moderate Reductions: | Finish forging and upsetting - 2200ºF (1200ºC). |

| Slight Reductions : | Coining, restriking and end upsetting - 2050ºF (1120º). |

| Type : | Chain Link, D Shackle, Bow Shackle etc. |

Other Properties of Titanium Alloy Grade 2 / Grade 5 Forgings

Equivalent Grades for Titanium Grade 2 / Grade 5 Forging

| STANDARD | WERKSTOFF NR. | UNS |

| Titanium Grade 2 | 3.7035 | R50400 |

| Titanium Grade 5 | 3.7165 | N56400 |

Titanium Gr 2 / Gr 5 Forgings Chemical Composition

| Grade | Ti | C | Fe | H | N | O | Al | V |

| Ti Grade 2 | 99.2 min | 0.1 max | 0.3 max | 0.015 max | 0.03 max | 0.25 max | - | - |

| Ti Grade 5 | 90 min | - | 0.25 max | - | - | 0.2 max | 6 min | 4 min |

Mechanical Properties of Titanium Gr.2 / Gr.5 Forging

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Titanium Gr.2 | 4.5 g/cm3 | 1665 °C (3030 °F) | Psi – 49900 , MPa – 344 | Psi – 39900 , MPa – 275 | 20% |

| Titanium Gr.5 | 4.43 g/cm3 | 1632 °C (2970 °F) | Psi – 138000 , MPa – 950 | Psi – 128000 , MPa – 880 | 14% |

People also search for DIN 3.7035 / 3.7165 Forgings

Titanium grade 2 bow shackle, titanium grade 2 forged circles, astm b348 grade 2 titanium forged discs, titanium 3.7165 seamless rolled rings, titanium alloy grade 5 forgings exporter, din 3.7035 double loop chain, titanium gr 5 forgings suppiler in india, titanium din 3.7035 bow shackle, titanium alloy gr.5 forgings price, titanium gr 5 forgings products manufacturer in gujarat, titanium alloy 3.7165 forged circles, titanium grade 2 forgings suppliers in vadodara, titanium n56400 d shackle with metric fine pitch, ti alloy gr 2 chain links, titanium alloy grade 2 shafting & bars, titanium gr 2 open die forging, titanium alloy gr.5 chain links suppliers in india, ti alloy r50400 closed die forging, titanium gr.2 forgings distributors, titanium alloy gr.2 crane hooks supplier, a wide range of the titanium grade 2 forgings price list, titanium grade 5 d shackles, uns n56400 forgings products supplier in india, grade 2 titanium forgings dealer.

Other Titanium Gr 2 / Gr 5 Forgings Types

Forged Hollow Bars, Forged Flat Bars, Joining Shackle, Safety Chain Shackle, Mandrel Rings, Step Shafts, Single Jack Chain, Seamless Rolled Ring, Lifting Chain, Shafting & Bars, Forged Discs, Open Die Forging, Crane Hooks, Double Loop Chain, Special Bow Shackle w/ No-Snag Pin, Forged Circles, Forged Circular Plates, Closed Die Forging, Anchor Shackle, Long Link Chain, Bolt Chain Shackle.

Quality Assurance of Titanium Alloy Grade 2 / Grade 5 Forgings

Titanium Gr.2/Gr.5 Forgings are manufactured and controlled to international standards such as ASTM, ASME, BS, MSS, EN, DIN or WERKSTOFFE. Our products undergo stringent quality tests before they are dispatched.

Oil, Gas & Energy Fastener Specialists

OUR STRENGTH IS YOUR CONFIDENCE